Continuous Sintering Furnace are used for the Sintering of Green Metal Parts, obtained through the compaction of various Metal Powders. In this process, Gradual Heating of Metal Parts is carried out under the Controlled / Reduced atmosphere, to Burn-off the Binder / Lubricant & to impart strength in Metal Compacts by Bonding of the particles. The Sintering Temperature is much below the Melting Point of the major constitute of the Metal Compact.

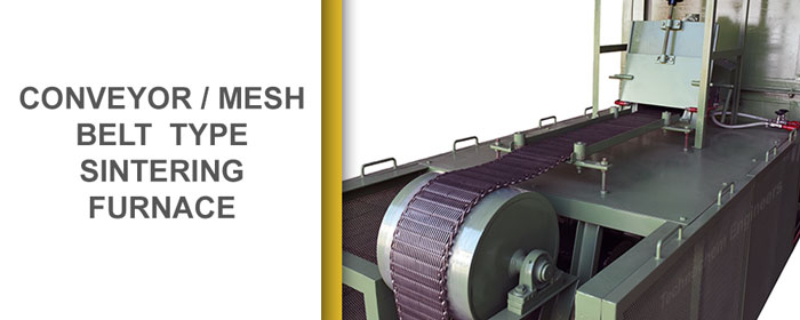

Mesh Belt / Conveyor Type Sintering Furnaces are offered as per our clients application i.e. the processing time, temperature, capacity, size of the muffle etc. are customized as per customers specific requirements.

Maximum Operating Temperature offered for Sintering Furnaces up to 1120o C

These Furnaces have Pre-heat Zone, Hot Zone, Jacketed water Cooling Zone, Feeding and Exit Doors, Flame Curtains, Control Panel etc. suitable for maintaining the required Atmosphere inside the muffle.

Features of Sintering Furnace :

- Muffle – Muffles are provided to maintain a controlled / reduced atmosphere for the sintering process. These are made of Heat Resisting Stainless Steel or Inconel as per the customer’s requirement.

- Electric Heating – Our Furnaces are Electrically Heated. Electrical heating has clear advantages over fuel-fired heating as it is the most efficient, easy to operate, clean & it avoids the hazards and problems associated with using any other fuel. It is also environment friendly and pollution free.

- Cooling Zone – Water-Jacketed type Cooling Zones are provided in our furnaces, to cool Down the Sintered Parts to a desired temperature for ease of further handling.

- Conveyor / Mesh Belt – Conveyor belt is provided for smooth conveying the Compacted Parts across the various Zones of the furnace at desired speed. Belts are procured from reputed Multinational Company, to ensure a very high quality and reliable product.

- Temperature Controlling – Temperature of all the zones are controlled with the help of AI Based controllers. So that the temperature is maintained precisely and it also results in increased efficiency and power saving.

- Thyristor Control – Thyritor based controllers enhances the life span of Heating Elements, as they prevents the ON/OFF of the heating elements and thus prevents the Thermal Shocks to the Heating Elements. Thyristors also helps in reducing the maintenance costs of Electrical component. They also reduces the Maximum

Demand (MD) & electrical consumptions during furnace operation.

- Temperature Overshoot – A secondary protection system can be provided in each Heating Zone to prevent the Overshoot of Temperature, in case of failure of primary temperature controlling system. This system will override the primary controlling system & will shut off the complete system to prevent any damage to the furnace / Heating Elements due to over heating.

We also Manufacture below type of Furnaces :